We explain what sustainable supply chain management is, and what it means to your business and customers.

Simply claiming your operation is 'sustainable' or 'green' isn't enough anymore. Your clients, customers, and even your staff members, want to actually know how you are sustainable.

Last month I was at a conference and a fellow attendee who was familiar with our various lines of work stopped us to chat for a little bit. He had just received a form from one of their customers which he wasn't sure what to make of.

We took a quick look at the multi-page form which was asking about a number of things which the recipient had never been asked before. His company was being asked to voluntarily complete the form, and return it to their customer. They were asked to identify suppliers within their own supply chain, and disclose some information about how they do business.

What really caught my attention, and I let my fellow attendee know what the underlying message of this document was, was that the future of them doing business together with this client could depend on what they disclosed in that document.

I told him, they're looking to create a supply chain of environmentally friendly organizations and wondering whether or not doing business with you is right for them.

What is sustainable supply chain management?

Supply chain management is an indispensable part of a business’s sustainability program. Knowing the level of environmental, social, and economic impact and viability of your vendors and customers is becoming increasingly common as all industries move towards a more sustainable future. Government pressures are unlikely to be the driver of this change, but you're already seeing corporate pressures on suppliers and vendors.

Companies are striving to operate in a more sustainable manner. There's no denying that going green and being environmentally friendly is the way of the future. And, in order to meet the future head on, companies are making their products or delivering their goods or services in a way that doesn’t impact the environment, that doesn’t deplete natural resources, that doesn’t contribute to climate change, that doesn’t contribute to social inequalities or injustice, and that in general, is done “the right way”.

One of the ways a company does this is by looking at their entire manufacturing process (when I say manufacturing, I mean anything from a product to a service), from where the raw materials are obtained, through the entire process within the plant, to the use and ultimately disposal or recyclability of their product or service. We might call this evaluating the process from “cradle to cradle” (thinking beyond cradle to grave) or on a “life-cycle assessment” type analysis.

Really, companies are looking at every aspect of the way they, and even you, do business.

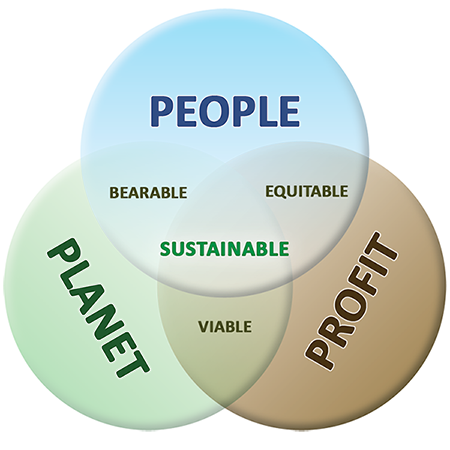

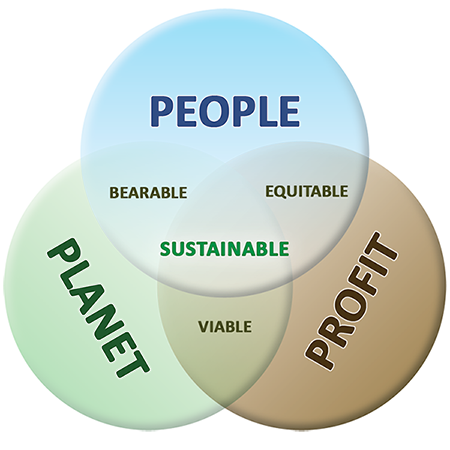

And that includes things you might not think of when you think of sustainability. Not just environmental factors, but also things like social factors and economic factors. Obviously, if your raw materials are extracted by forced child labor in a third-world country, and your business with that source is keeping them going, then you’re not running a sustainable business, no matter where you’re located or what you say. A bit of an extreme example, but I think you get the point.

One aspect of running a sustainable business is your supply chain. Who do you get your raw materials, your supplies, the things you need to make your operation go from? For example, it could be rare earth minerals extracted from central African countries that you use to make electronic components. Or, it could be locally harvested vegetables you serve in your restaurant. Or, it could be the cleaning products on the shelf in your store. Where did those materials come from, and under what conditions?

Companies large and small are asking these questions about themselves, and their suppliers. They're looking at creating supply chains of top performers with the ultimate goal of using them to create a better, more environmentally sound, and ultimately more profitable company.

Determining a way to find out, and creating a policy based on how sustainable you want to be, is the essence of sustainable supply chain management.

Simply put, you want to do business with people and businesses that do things the right way, and avoid altogether those who don’t. You really can’t run a sustainable operation yourself any other way.

Sustainable Supply Chain Management Implementation

You could almost envision this as having the following steps:

- Develop some form of a sustainability plan for your business. What are your goals and objectives, and how do you want to go about them?

- Include your supply chain in your considerations of how sustainable you are. Supply chains are part of your operation, environmentally, socially, and economically.

- Develop a policy for your suppliers and customers. This is up to you, but you should at least be looking at some basic indicators of sustainable operations, whether it’s environmental impact, waste disposal, energy use, employee and community social factors, whatever. It’s your call. But make a policy and stick to it.

- Then, go out and evaluate your supply chain (this probably means a survey of some sort). How do they stack up, and more importantly, what are you going to do about it? The customer of my fellow attendee made it clear that they were making their buying decisions based on the answers. You do the same, figure out where you draw the line. Is your choice price only (not sustainable), or solely based on the sustainability level of your suppliers (bold move), or some combination thereof?

- Then, go back to your supply chain and take appropriate action. Who knows, they might surprise you with some changes towards sustainability themselves.

So what types of things were on my fellow conference attendee’s request for information? Questions about environmental practices, such as how much they recycled, how much solid waste they generated, how much energy they used, etc.

Notice that these questions had to do with environmental regulations? That's because it's expected you're already following all applicable regulations. If you're not, you might as well consider that customer gone.

There was one question about compliance: can you confirm you are in full compliance with all applicable environmental regulations? How many companies out there can answer that truthfully?

There were also questions about labor practices, minority hiring, community support, volunteering, employee education, and safety practices and records. Remember, sustainability isn't just about being green and environmentally friendly. Remember the triple bottom line of people, planet, and profit.

There were some additional questions about whether the facility had an Environmental Management System in order to manage and reduce their environmental impacts. There was room to describe if it had been certified to any 3rd party standard recognized standard, obviously implying extra brownie points for having a real, credible EMS.

All in all, the form was complex and lengthy.

Developing A Supply Chain of Sustainable Businesses

My fellow attendee was pretty concerned since this was their primary customer, and he let it be known to us if they lost this customer, they would be in real trouble. He said they’d have to review this form carefully, and maybe make some real changes to retain this customer’s business.

But guess what? That’s the idea! Do business with the better organizations, and stop doing business with those who act like it's the 1950s. Corporate pressures, collectively, will make us all more sustainable. I don’t care what your line of business is, if you haven’t gotten one of these forms, you will. Soon. And when you do, if you value this customer’s business, you too may have to make some changes at your business in order to meet the demands of tomorrow's customers.

And that’s a good thing for everyone.

If you want to become more sustainable, or if you just don’t want to lose business in the future, you ought to consider a corporate sustainability program, including sustainable supply chain management. As part of that, you’ll want to take a close look at your suppliers and vendors. Are they sustainable themselves? If not, your actions will continue this ever-expanding web of corporate pressure towards a sustainable future.

Who knows, one day you might be the one sending out the forms, instead of receiving them. You’ll be the one driving a more sustainable future. And that, too, will be a good thing.

To learn more about sustainability, click here to contact us or give us a call at 609-693-8301 to discuss your company's sustainable future.